| An

Introduction to Mitered Laminate Designs in Marquetry

by Ernie Mills.

.PDF File

|

The following is my attempt at adapting the

woodworkers build procedures in Laminate Designs to thin veneer,

0.020" Marquetry.

It must be mentioned that the following was done using only a

Scalpel which introduced it's own set of cutting problems but the

bonus was zero kerf.

Written for the woodworker, Laminated Designs in Wood

by Clarence Rannefeld explains this art

form in great detail. It includes techniques, patterns and projects

with in-depth theory and mathematics.

Woodturner PRO is a fantastic piece of software.

It comes in three modules the relevant one to this article is

Lamination PRO. ~

http://woodturnerpro.com/ ~ |

| Every design starts

with a Zig-Zag |

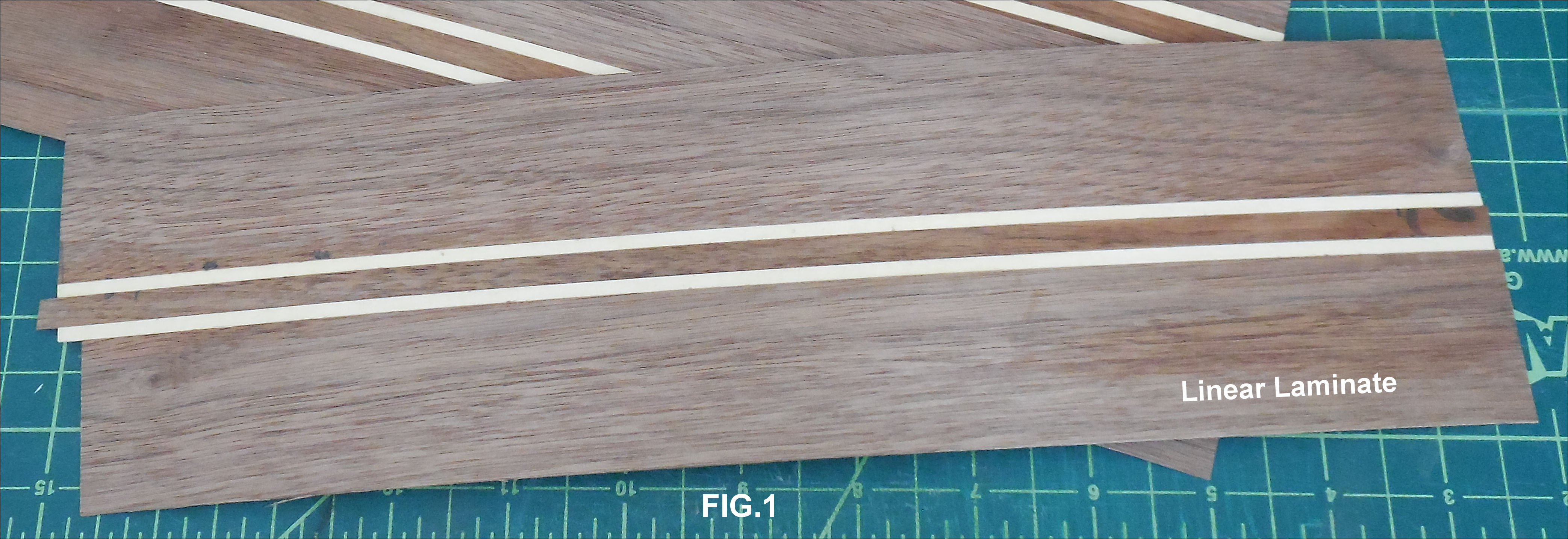

So in my experiments I cut out enough veneer to make 4

Linear Laminates about 18" long.

The center stripe has 3 strips. 1/8" holly, 1/4" walnut and

another 1/8" holly. The outboard planks were 1-1/2" walnut.

Complex designs can include more stripes in the Linear

Laminate. |

|

|

| Assembled Linear

Laminate |

'Standard' stringer cutting to produce these. |

The image below

shows the simple jig for cutting the strips. In this case I

chose 30° to the vertical. The

inverted 18" rule is taped secure

such that the Linear Laminate

being cut slides underneath it. The 12" ruler acts as a stop

and the gap is set for the Laminate Cut Width,

in this case 1/2". I added a piece of veneer to act as a

fence. This is set to 30°. I found that you

really don't need this guide since alignment with the

Stop ruler

seemed to be accurate, however I kept the fence as a double

check. Throughout this whole procedure accuracy is

paramount. My failure, which can be seen on in figures 5, 6

and 7 as heavier cut lines. These were an artifact produced by the blade not being vertical and a "V" is

evident. I got away with it in this example since after

sanding, sealing and varnishing this affect appears to have

disappeared. This was my laziness in not holding the knife

perfectly vertical. My excuse is that this was all

experimental. My next one should be corrected.

OK, after cutting all the strips,

FLIP EVERY OTHER ONE OVER and glue. One thing I

learned was to glue these using cutting board squares as

guides to keep them aligned. That was another mistake I made

and I had to remake whole Linear Laminates. |

|

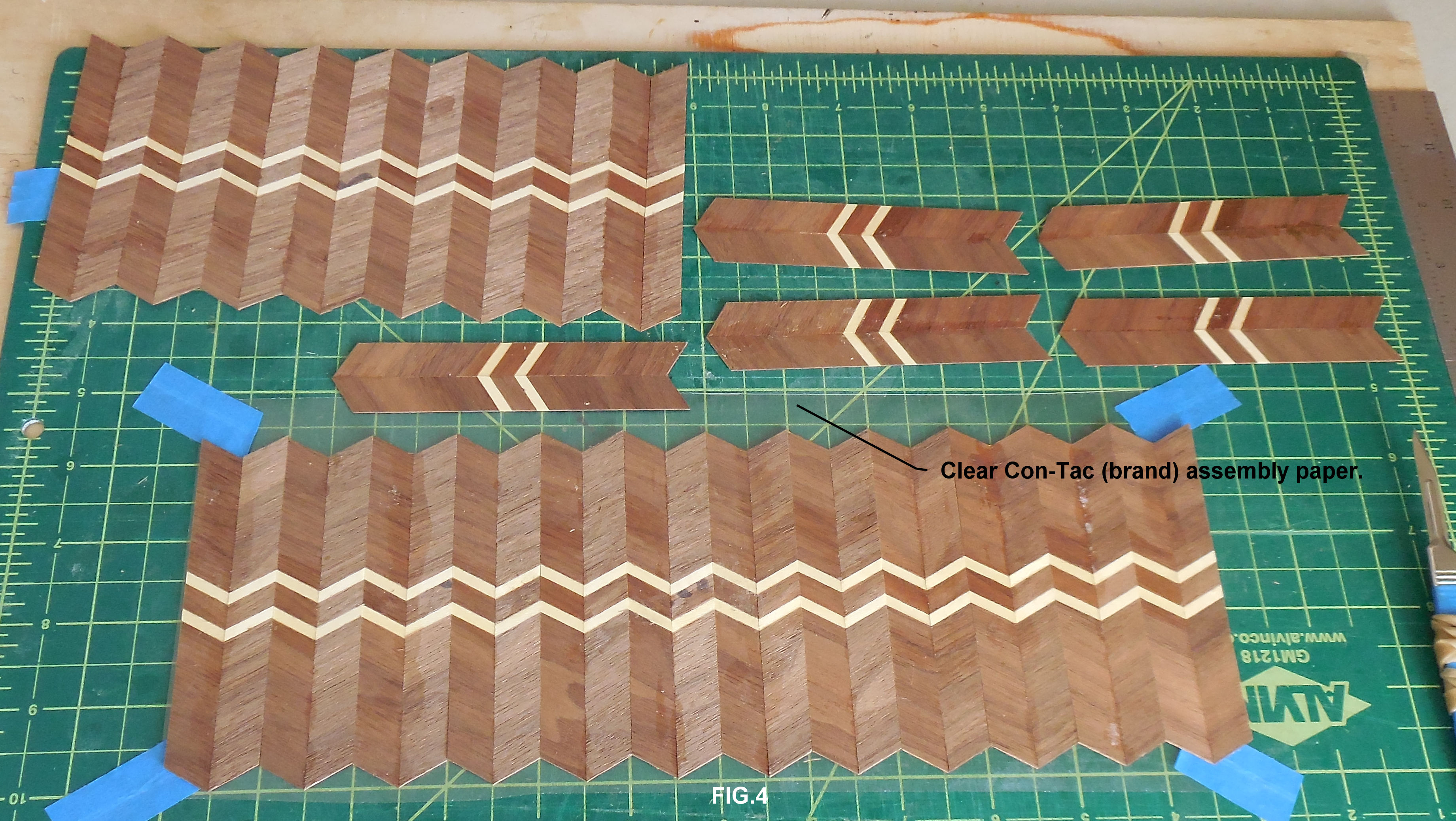

| The following image shows the

FIRST GENERATION achieved. The

Zig-Zag |

| OK, again accuracy is paramount in the

assembly of these pieces. I find it easier to assemble the

pairs first but make sure each pair is assembled dead-on.

Any error in the stage before will multiply in further

stages. You might notice on figure 4 that the assembly is

done on a piece of Clear Con-Tact (brand) paper taped down

with the 'sticky' side up. This is

the same technique you use for assembling the Louis Cube

pattern. When assembling the First Generation Laminate

on this paper make sure that the points line up with the

horizontal lines on the Cutting Board and the Vertical

strips are aligned with the Vertical Cutting Board lines,

thus ensuring alignment accuracy. |

|

| How to MARK where

you need to cut to produce the Second Generation |

|

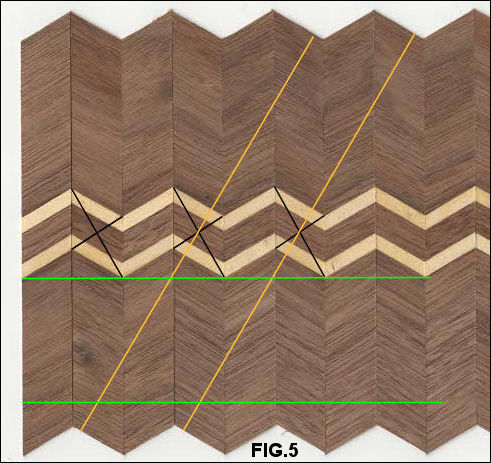

A word before we continue.

At this point you have a choice of cutting all your future

lines through the ASCENDING (A)

Line or the

DESCENDING (D) Line. This makes a

big difference to the final pattern. In my case I decided to

cut through the DESCENDING line.

The method I developed for Marquetry is simple and certainly

easier than the woodworkers who are working in 3/4" stock

with a complex jig.

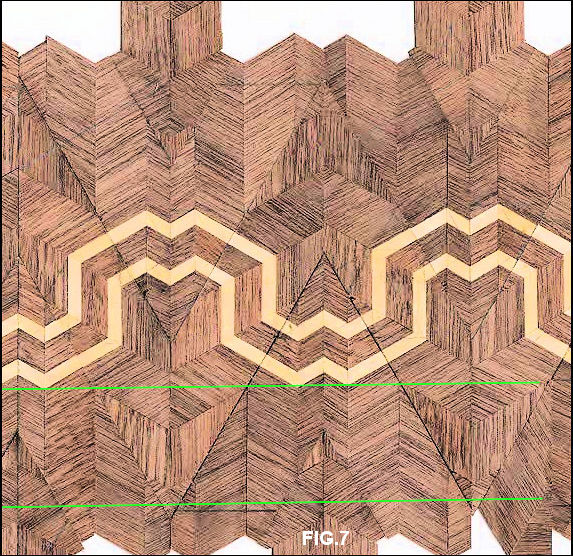

With a pencil draw the all important Black Lines

to show the centers of the DESCENDING

strips. Where they intersect should be the middle and where

your cut will pass through.

The top green line shows why you needed to glue these strips

using a straight edge. Below that line and parallel to it in

pencil draw another line by using a wide ruler. (shown in

green)

In my case I am going to cut 30°/D

to make the Second Generation.

Simply tape a rule along the bottom line and with a 30°

plastic triangle draw a pencil line as shown in Orange.

Now cut along the these liunes shown in orange.

FLIP EVERY OTHER PIECE and you

will produce your Second Generation Laminate. |

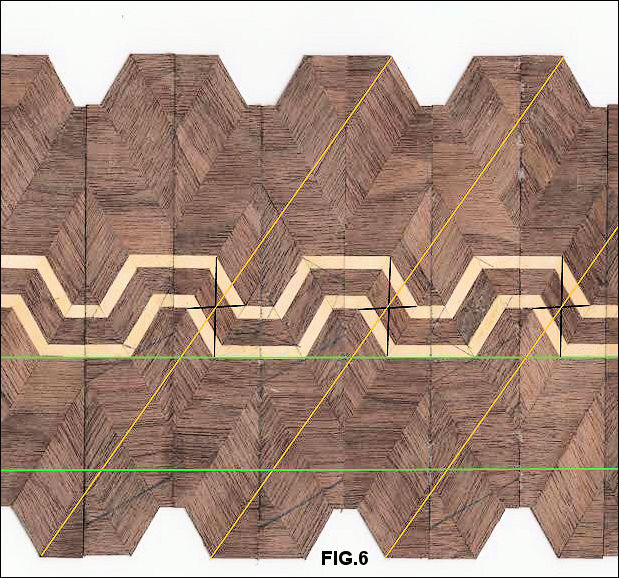

Do the same as the above with each

Laminate

This image shows where to cut the Second

Generation

Laminate to produce your Third Generation

Laminate. |

|

| |

|

Congratulations,

you have produced a Third Generation Laminate.

You can of course continue ad infinitum.

OK, A word about Formula and being

able to pass on your pattern to

someone else.

As you know you can choose to cut through the

ASCENDING (A) Line or the

DESCENDING (D) Line, and you can

do this at any angle so there are many combinations and

Patterns.

The formula for this piece is therefore 30/30D/30D

ie cut the Linear Laminate 30°,

the First Generation Laminate 30/D (30°

DESCENDING) and the

Second Generation 30/D

(30° DESCENDING) |

| So! now what do I do with this

Laminate? |

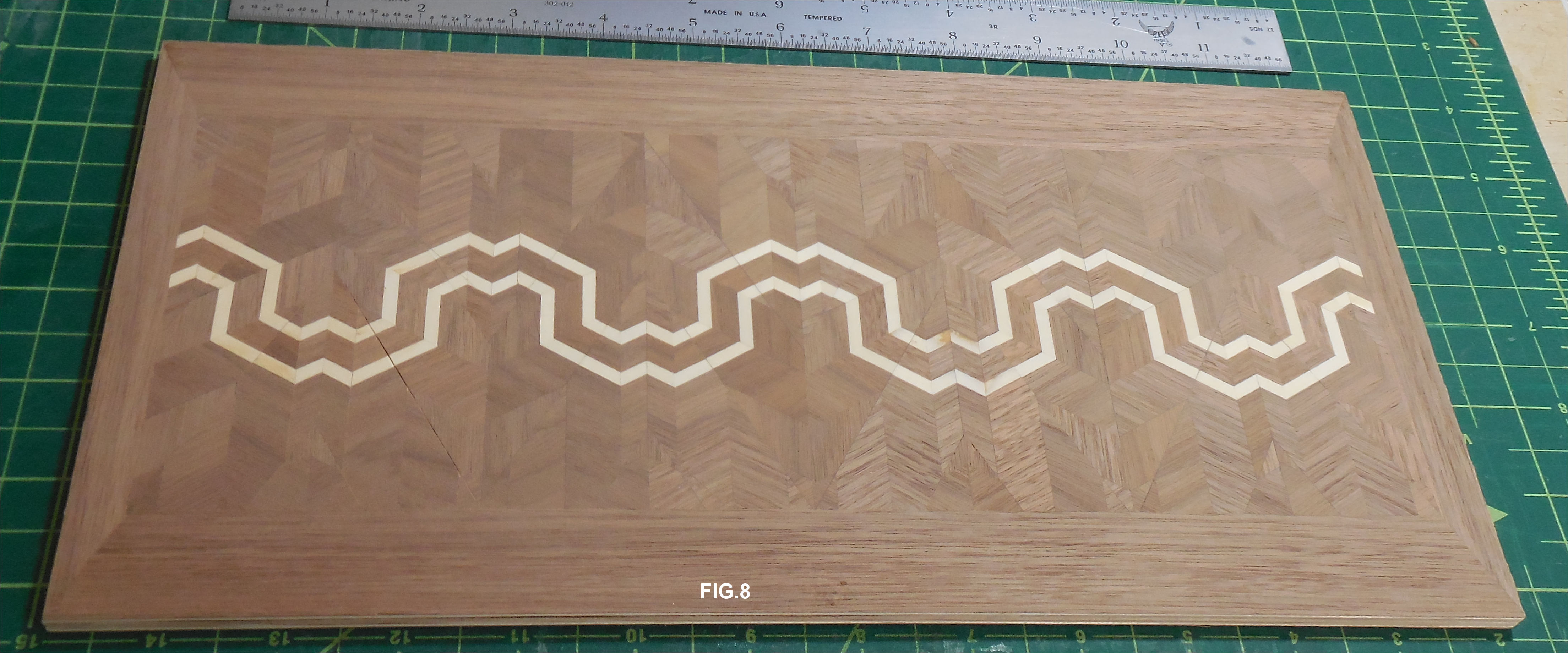

| The image below shows the Laminate with a

normal Marquetry border and

pressed onto a piece of 1/4" MDF.

The backside had a piece of walnut veneer pressed onto it. |

|

The Tray turned out to be small so I called

it a Liqueur Serving Tray.

I refer you back to the book, Laminated Designs in Wood

shows many applications. A clock, a table and much

more. |

Please note that the Tray was an after thought after working

through this adaptation of Laminated Design for Marquetry

and I would be very interested in receiving and image via

email of your finished work using this technique. I'll add

it to my web site. Enjoy |

|

|